Construction robots enhance efficiency

For the Trunk Road T2 & Cha Kwo Ling Tunnel project, the Civil Engineering & Development Department has applied innovative technologies including an autonomous air-ground co-operative tunnel inspector and a drilling robot.

Efficiency boost

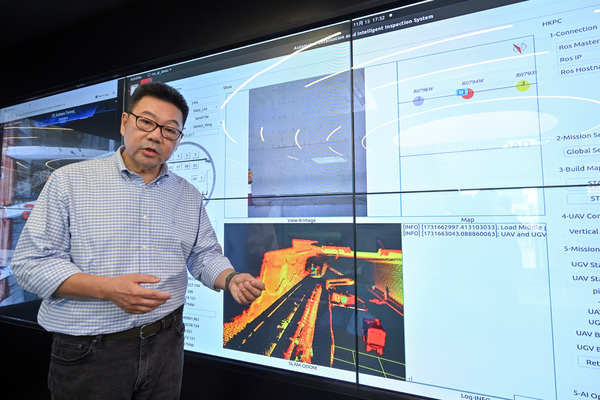

Giving rein to the synergy of artificial intelligence (AI), robotics and total-station positioning techniques, the autonomous air-ground co-operative tunnel inspector can automatically carry out all necessary tunnel inspections, covering tunnel linings and various tunnel internal structures in a safer, more efficient and cost-effective manner.

Consultancy company Senior Resident Engineer Albert Sung explained that the system is equipped with ultra-high-definition cameras to automatically capture images of the tunnel’s internal structures.

“The aerial drone focuses on the upper half of the tunnel, while the unmanned ground vehicle focuses on the lower half, enabling 360-degree full coverage of the tunnel. These images are transmitted in real time to the AI module on the unmanned ground vehicle for defect detection.

“It can instantly and accurately detect millimetre-level defects and generate electronic reports. The entire process is 23 times faster than conventional methods and reduces inspection costs by 50%.”

The system was co-developed by the Civil Engineering & Development Department, a consultancy firm and the Hong Kong Productivity Council and has obtained three patents as well as receiving multiple local and international innovation awards, including 2025 Gold Edison Award.

Rapid robots

In addition, the tunnel project employs an automatic drilling robot that improves efficiency by reducing time and labour costs.

Civil Engineering & Development Department Engineer Kelvin Ma explained that, in the past, before constructing the corbel for overhead ventilation duct slabs inside a tunnel, workers had to repeatedly carry out tasks such as chiselling the concrete surface, and positioning, drilling and installing anchor bolts, while working on elevated platforms.

“The Trunk Road T2 project has introduced an automatic drilling robot. Using laser scanning technology for precise positioning, the robot performs accurate drilling and anchor bolts installation on tunnel walls and ceilings while simultaneously extracting dust generated during the process.

“Compared to traditional methods, which involve manual lifting and installation, the adoption of the Multi-trade Integrated Mechanical, Electrical, & Plumbing and drilling robot has reduced onsite labour requirements by 60% and shortened the associated construction time by 40%.”

Tech application

With the rapid development of robotics technology, the Development Bureau is encouraging the application of construction robots in all public works projects.

Development Bureau Chief Assistant Secretary Felix Poon stressed that the bureau prioritises the promotion of highly-effective construction robots that demonstrate high cost-effectiveness, scalability and necessity for onsite construction.

“We first pilot construction robots for different tasks in some public works projects. Based on the outcomes of the trials, we mandate their application for suitable public works projects.

“In addition, the Government provides subsidies to the private construction sector. This measure gradually establishes a robust ecosystem for the development of construction robots.”

Mr Poon added that the bureau will soon implement a policy requiring suitable construction robots to be adopted in all public works projects, with the aim of enhancing the overall quality, safety and productivity of construction projects.