Cutting edge tech boosts efficiency

Every year, some 600,000 tests are carried out on materials used in government public works projects. To meet the increasing demand for tests, the Civil Engineering & Development Department’s Geotechnical Engineering Office (GEO) and the Logistics & Supply Chain MultiTech R&D Centre have developed two automated systems for testing concrete cubes and steel rebar respectively.

World's first

The Automated System for Concrete Cube Testing is the first of its kind in the world to include the whole set of testing procedures. With four water tanks for storing up to 12,000 concrete cube specimens, the system can identify the location of every single specimen by radio frequency identification.

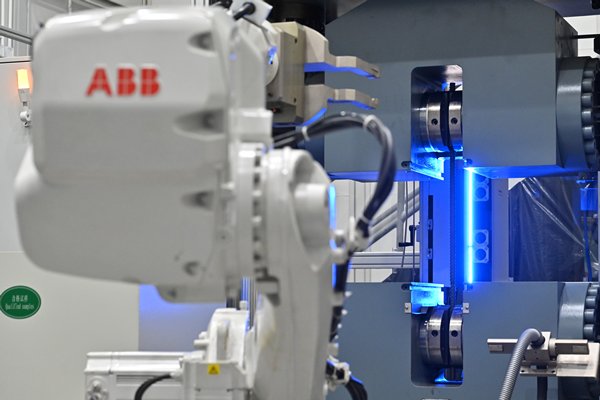

On testing, a concrete cube is first plucked out of the water tanks by a robotic arm. After air-drying the water off its surface, laser sensors then measure its dimensions before undergoing a compression test.

By setting up three cameras at different angles on the compression machines, the system captures the fracture patterns of the concrete sample upon completion of the compression test.

A computer vision-based method with the help of artificial intelligence then processes the results of the test to determine whether the fracture pattern in the sample meets construction standards. All testing data will be uploaded to a computer system instantly.

Compared with doing it manually, the automated system has several advantages for testing a large number of specimens including a reduction of variability in the data gathered, fewer errors made and a decreased amount of manual work.

Cutting edge

Besides the concrete cube testing system, there is also Hong Kong’s first Automated System for Steel Rebar Testing.

With the new system, a robotic arm first puts a steel rebar into the testing machines and optical extensometers then measure in real time the strain that the steel bar comes under during tensile testing.

GEO Head Raymond Cheung said the Automated System for Steel Rebar Testing can currently handle half of the government’s demand for tests while the Automated System for Concrete Cube Testing can handle around 20%, with the remaining tests being carried out manually. But there are big plans to upscale the concrete cube testing system to satisfy half of all testing demand in future.

He expected that the two automated systems would serve as examples and encourage the construction industry to enhance its efficiency and quality by making wider use of innovation and technology.